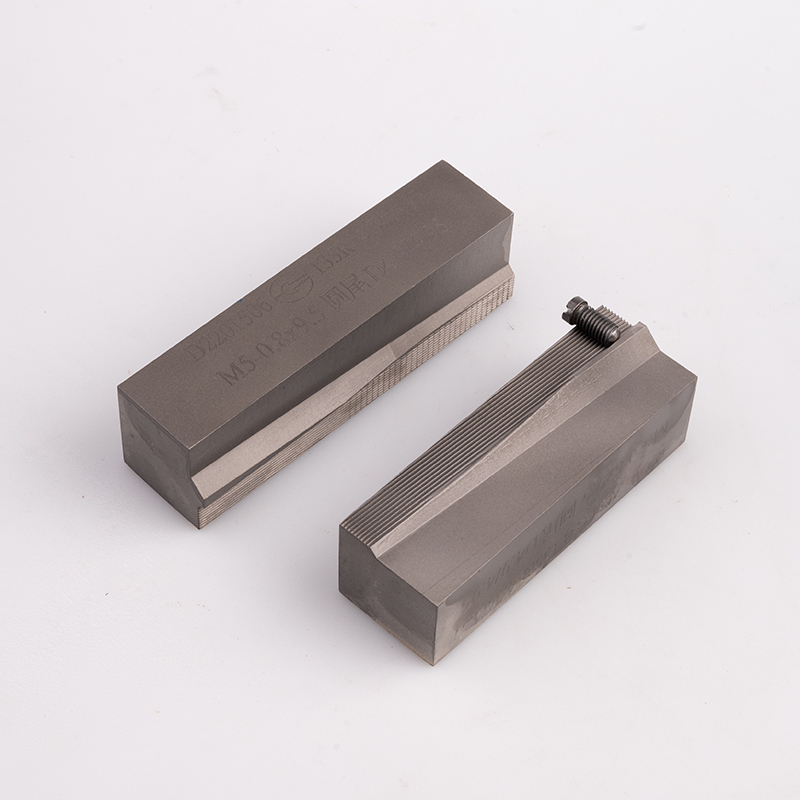

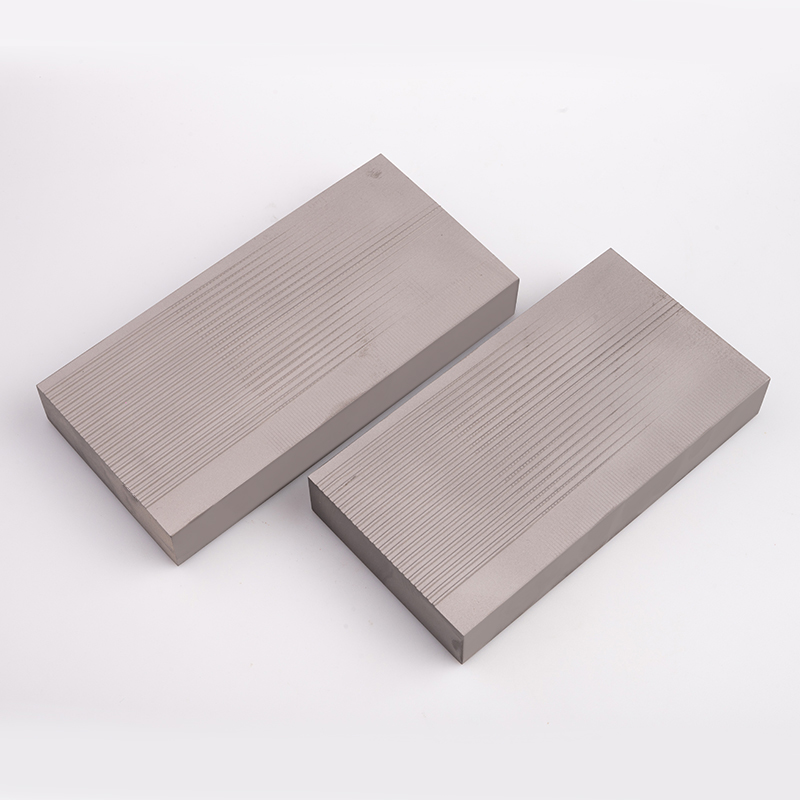

China Factory High Precision Cold Heading Dies Tungsten Steel Teeth Insert

Materials

Dies are typically made from high-strength, wear-resistant tool steels or carbide materials. Common steel types include:

D2 Steel:Known for its hardness and wear resistance, suitable for cutting and forming operations.

H13 Steel:Offers high toughness and heat resistance, often used in hot working applications.

Carbide:Extremely hard and wear-resistant, used in high-precision and high-wear applications.

Manufacturing Process

Design:Detailed design using CAD software to ensure precision and functionality.

Material Selection:Choosing appropriate materials based on the application and required properties.

Machining:Initial shaping of the die using processes like milling, turning, and grinding.

Heat Treatment:Processes such as quenching and tempering to enhance material properties like hardness and toughness.

Finishing:Precision machining, including EDM (Electrical Discharge Machining) and polishing, to achieve the final dimensions and surface finish.

Assembly and Testing:Assembling die components and conducting trial runs to ensure proper functionality and performance.

Applications

Main dies are used in various industries, including:

Automotive:Producing body panels, engine components, and other parts.

Electronics:Manufacturing casings, connectors, and other intricate parts.

Aerospace:Creating components for aircraft and spacecraft with high precision.

Construction:Forming structural components and fittings.

Consumer Goods:Producing a wide range of products from household appliances to personal gadgets.

Product Attributes

Place Of Origin : China

Company Type: Manufacturer

Customized Support : OEM, ODM

Certification : ISO9001:2015

Model Number :Various Type

Trial Order: Accptable

Packaging & Delivery

Hot Sale Tungsten Carbide Die ...

Hot Sale Tungsten Carbide Die ...  China Factory High Precision C...

China Factory High Precision C...  Good Quality Tungsten Carbide ...

Good Quality Tungsten Carbide ...  1 Die 2 Blow Heading Machine T...

1 Die 2 Blow Heading Machine T...  Good Quality Tungsten Carbide ...

Good Quality Tungsten Carbide ...  Bolt Forming Die Screw Header ...

Bolt Forming Die Screw Header ...  TiALN Coated screw Header Punc...

TiALN Coated screw Header Punc...  Hot sale TiALN Coated Screw ...

Hot sale TiALN Coated Screw ...  SKH-9 M42 Material TiALN Coa...

SKH-9 M42 Material TiALN Coa...  HOT SALE Screw Header Punch Fo...

HOT SALE Screw Header Punch Fo...  Cylindrical Thread Rolling Die...

Cylindrical Thread Rolling Die...  Screw Mold Nut Forming Die col...

Screw Mold Nut Forming Die col...  Screw Mold Nut Forming Die col...

Screw Mold Nut Forming Die col...  Factory Customized SKH-9 DC53 ...

Factory Customized SKH-9 DC53 ...  Factory Customized Skh-9 Flat ...

Factory Customized Skh-9 Flat ...  Thread Rolling Die for machine...

Thread Rolling Die for machine...  Thread Rolling Die For Machine...

Thread Rolling Die For Machine...  Thread Rolling Die For 21-Slot...

Thread Rolling Die For 21-Slot...