The difference between SKD11 and SKD61

Date: 2025-02-26 Categories: Industry News Hits: 249

SKD11 is a high-carbon and high-chromium cold-working die steel, and SKD61 is a medium-carbon and high-alloy hot-working die steel. 2. The two are used in different scenarios. SKD11 is suitable for the production of some punches for hardware molds, and Skd61 is mainly used for the core material of die-casting molds. 3. The hardness after heat treatment is different. The hardness of SKD11 is about 58 degrees to 60 degrees, and the hardness of SKD 61 is between 48 degrees and 52 degrees. 4. The wear resistance and toughness are different. Under the same hardness, the wear resistance of SKD11 is better than that of SKD 61.

Hot Sale Tungsten Carbide Die ...

Hot Sale Tungsten Carbide Die ...  China Factory High Precision C...

China Factory High Precision C...  Good Quality Tungsten Carbide ...

Good Quality Tungsten Carbide ...  1 Die 2 Blow Heading Machine T...

1 Die 2 Blow Heading Machine T...  Good Quality Tungsten Carbide ...

Good Quality Tungsten Carbide ...  Bolt Forming Die Screw Header ...

Bolt Forming Die Screw Header ...  TiALN Coated screw Header Punc...

TiALN Coated screw Header Punc...  Hot sale TiALN Coated Screw ...

Hot sale TiALN Coated Screw ...  SKH-9 M42 Material TiALN Coa...

SKH-9 M42 Material TiALN Coa...  HOT SALE Screw Header Punch Fo...

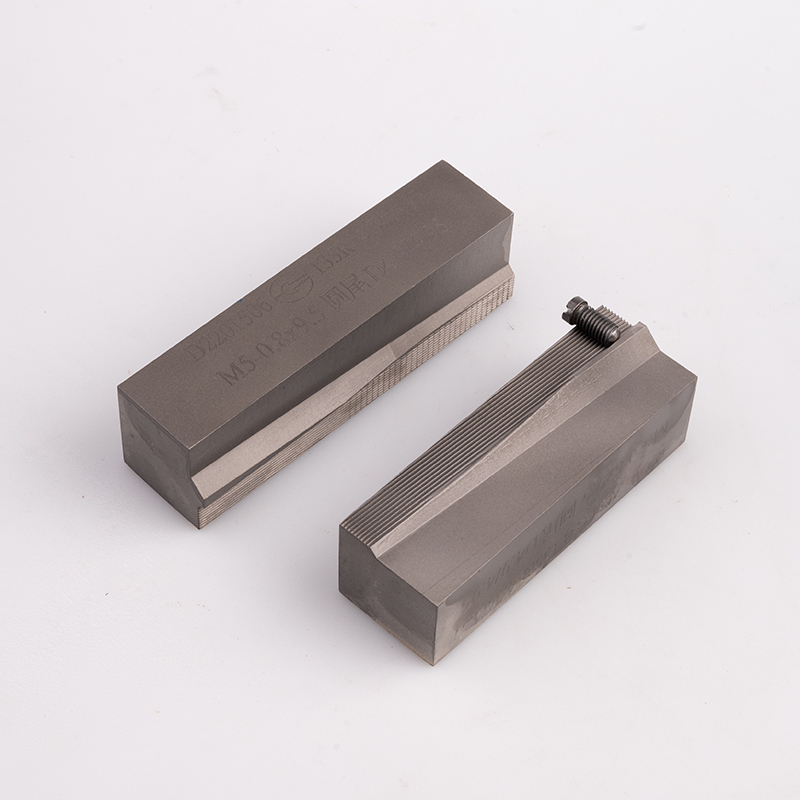

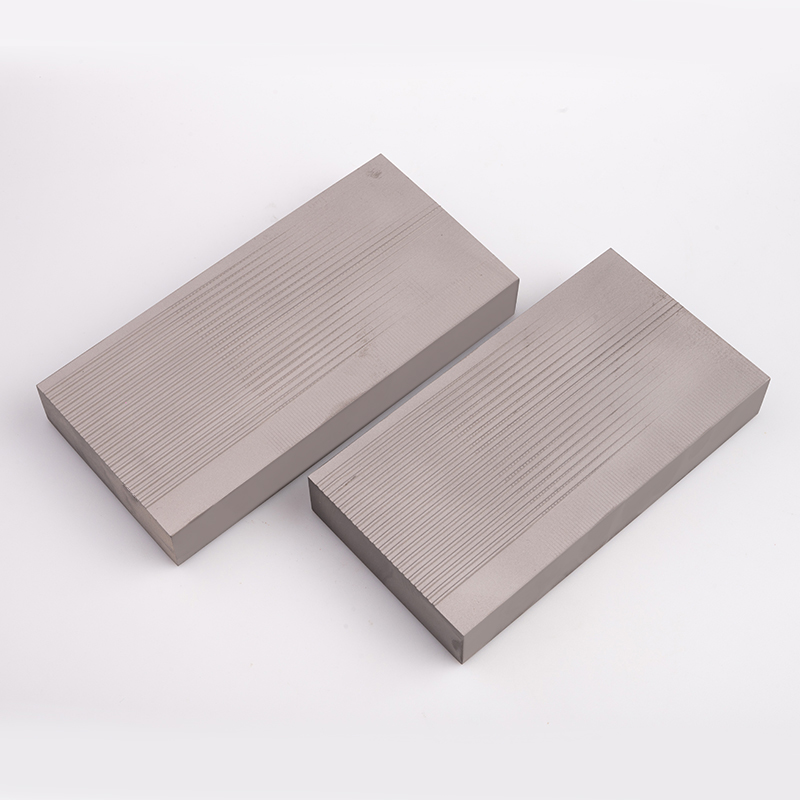

HOT SALE Screw Header Punch Fo...  Cylindrical Thread Rolling Die...

Cylindrical Thread Rolling Die...  Screw Mold Nut Forming Die col...

Screw Mold Nut Forming Die col...  Screw Mold Nut Forming Die col...

Screw Mold Nut Forming Die col...  Factory Customized SKH-9 DC53 ...

Factory Customized SKH-9 DC53 ...  Factory Customized Skh-9 Flat ...

Factory Customized Skh-9 Flat ...  Thread Rolling Die for machine...

Thread Rolling Die for machine...  Thread Rolling Die For Machine...

Thread Rolling Die For Machine...  Thread Rolling Die For 21-Slot...

Thread Rolling Die For 21-Slot...